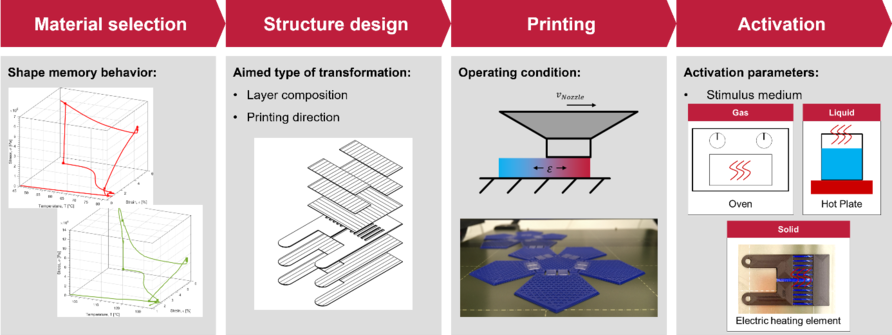

4D printing with fused deposition modeling is a methodology to fabricate transforming structures. During the printing process, the material is stretched and residual stresses are programmed in each line. These stresses can be released by thermal activation, which causes the structure to transform its shape. Recent research showed the influence of the printing parameters on the shape transformation. However, more than just the printing parameters influence the 4D structures behavior. In the present study we introduce a methodology which describes the influencing parameters in four sections: Material Selection, Structure Design, Printing and Activation. The methodology aims to simplify experiment planning, research reproduction and research comparison in 4D printing with FDM.

F. Cerbe, M. Sinapius, M. Böl

Methodology for FDM 4D printing with thermo-responsive SMPs

Materials Today: Proceedings 2022 [Link]