Contakt person: Isabelle Kuhr

The switch from petrochemically derived raw materials to renewable raw materials is essential in many areas. Using natural fibers in composite materials as a substitute for conventional fibers such as glass or carbon fibers is becoming attractive for a wide range of applications, particularly due to the environmentally friendly recycling options with comparatively little effort. Natural fibers also have a low density, which makes them particularly interesting for lightweight construction. However, natural fiber composites have significant disadvantages regarding moisture resistance, impact and fatigue behavior. The use of nanomaterials can significantly improve the mechanical properties of these materials, making them suitable for many applications in the automotive industry, aviation, and construction sectors.

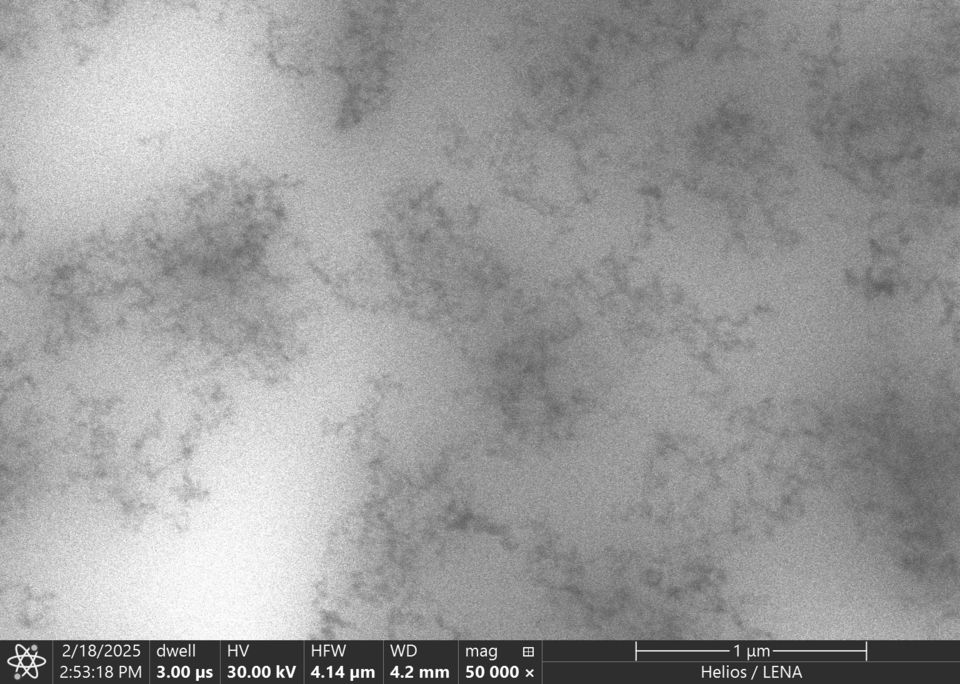

The nanomaterials can be introduced into the material in various ways, e.g. by adding them to the matrix or as a coating on the fibers. It is important to ensure that the nanoparticles are distributed as homogeneously as possible and that their agglomeration is largely prevented. To guarantee this and ensure high compatibility, the surface of the nanoparticles can be chemically modified. At present, the focus of investigations is on bioepoxy resin composites reinforced with flax fiber fabric mats into which silica (SiO2) nanoparticles are introduced.

Fig.: a) STEM image of the silica particle distribution in the resin; b) SEM image of the uncoated flax fiber fabric.

Goals and tasks of iPAT:

Project partner: Institute of Lightweight Structures and Aircraft Design (IFL) at TU Braunschweig

Funding: This project is funded by the Faculty of Mechanical Engineering at TU Braunschweig as part of the 12+6 program.