Nominally hydrodynamically lubricated plain bearings are widely used in machines to reduce friction and increase efficiency. However, critical lubrication conditions can occur under certain conditions, particularly at low speeds and minimum lubrication. Despite their technical relevance, these conditions are often poorly understood and are therefore handled inefficiently. The challenge of contact under minimal lubrication is inherently multi-physical and involves fluid-structure interaction (FSI) involving lubricant hydrodynamics (including cavitation bubbles), elastic deformations of solid structures and frictional contact mechanics between the solid surfaces. In previous projects on contact mechanics, numerical and experimental results already indicated (link to Yan/Kassandra) that even small amounts of lubricant can be sufficient to achieve a significant lubricating effect.

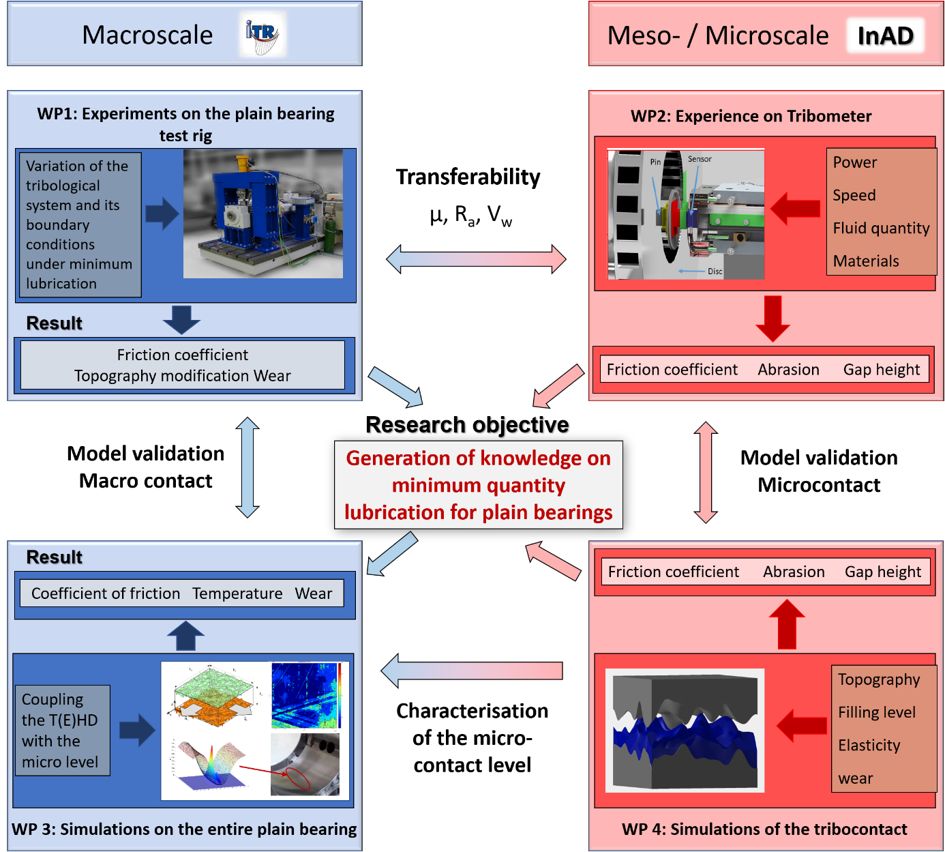

As part of a DFG-funded project, the Friction and Nonlinear Dynamics working group, in cooperation with the Institute of Tribology and Energy Conversion Machines (ITR) at TU Clausthal, is working on a multiscale analysis of plain bearings. The aim is to develop a consistent overall calculation model that is able to describe the wear of plain bearings under minimum lubrication and thus enable a deeper understanding of the friction-wear behaviour of plain bearings for these operating conditions.

To this end, experimental investigations are carried out on various scales, including macroscopic tests at the ITR and microscopic studies with pin-on-disc tribometers at InAD in order to analyse the wear of plain bearings under minimal lubrication. The continuous exchange of measurement data between the scales enables the holistic consideration of global and local influences. Based on the experimental data, models are developed for micro and macro levels in order to describe the friction processes more precisely and to realistically depict the transition from mixed to boundary lubrication. The findings can also be applied to other tribological systems with minimum lubrication in the future.

Prölß, M., Schwarze, H., Hagemann, T., Zemella, P., & Winking, P. (2018) Theoretical and Experimental Investigations on Transient Run-Up Procedures of Journal Bearings Including Mixed Friction Conditions. Lubricants, 6, 105.

Müller, M., Stahl, L., & Ostermeyer, G.-P. (2018). Experimental Studies of Lubricant Flow and Friction in Partially Filled Gaps. Lubricants, 6, 110.

Tong, Y., Müller, M., & Ostermeyer, G. P. (2021). Investigations on the dynamic influence of the contact angle on frictional sliding processes between rough surfaces using NURBS and mortar-based augmented Lagrangian method. Tribology International, 158, 106889.

Tong, Y., Müller, M., & Ostermeyer, G. P. (2022). A mortar-based cavitation formulation using NURBS-based isogeometric analysis. Computer Methods in Applied Mechanics and Engineering, 398, 115263.

Vacancies of TU Braunschweig

Career Service' Job Exchange

Merchandising

Term Dates

Courses

Degree Programmes

Information for Freshman

TUCard

Technische Universität Braunschweig

Universitätsplatz 2

38106 Braunschweig

P. O. Box: 38092 Braunschweig

GERMANY

Phone: +49 (0) 531 391-0