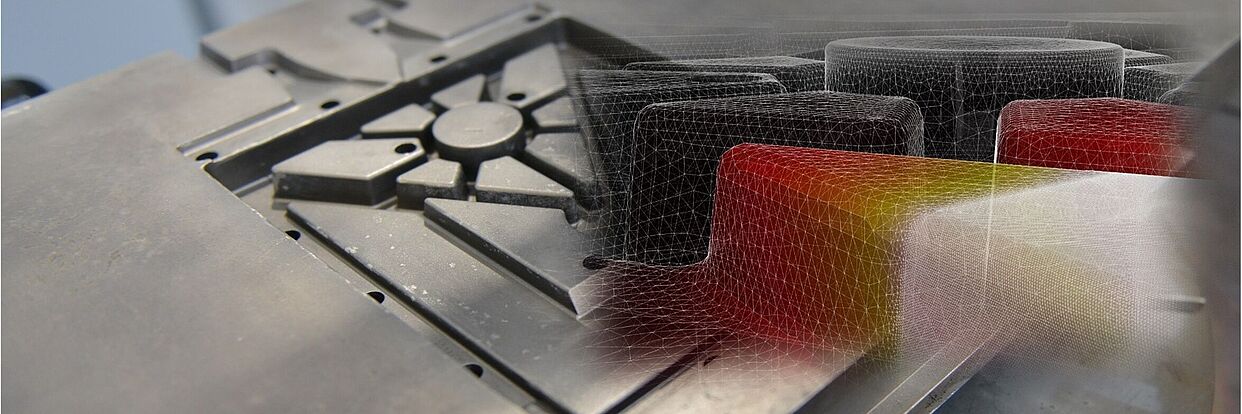

Hot work tool steels used in the die casting process are subjected to cyclically occurring stresses, which in turn can lead to die failures. The heat treatment of these steels has a decisive influence on the service life of the die casting die, since this determines the mechanical properties and thus the stress resistance. The state of the art is furnace-based tempering using a vacuum or inert gas atmosphere. However, there is often a conflict of objectives with regard to the optimum quenched and tempered condition during the heat treatment, since differently loaded die areas require a locally adapted quenched and tempered condition. A high hardness, for example, results in a longer service life due to the lower plastic content of the strain for a given strain range. With a high hardness, however, there is only a limited toughness of the material with a conventional heat treatment, which can lead to strong crack growth and thus to early failure, especially in notched areas of the die-casting die. Furthermore, in the case of fractured surfaces, much lower cooling rates and thus much poorer mechanical properties are often achieved in areas not surrounded by inert gas.

The aim of the project is to increase the service life of die-casting dies through local and demand-oriented heat treatment. In addition, the manufacturing costs for the production of die casting tools should be reduced. The overall technological concept is to completely replace the oven-based heat treatment in the production of dies by a surface heat treatment using electron-beam. This will be realized by using prehardened semi-finished products, which can already be manufactured to final dimensions before the surface heat treatment. The typical finishing or a costly erosion process to the final size of the die could thus be eliminated. In addition to the experimental determination of the heat treatment processes with the electron-beam machine, numerical simulations are carried out to estimate the resulting metallurgical microstructure and the hardness achievable with it.